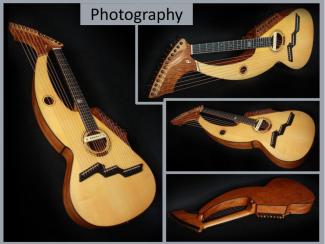

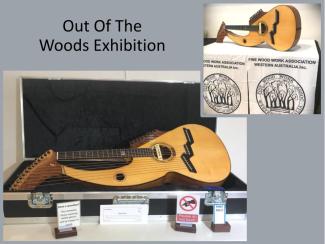

Building a 21 String Harp Guitar "Catania"

Wow! What a fantastic presentation.

Lou took us from the inspiration for the project, an article in the American Lutherie Journal, through the planning, jigs, construction and finish of this beautiful musical instrument. We even got a demonstration of how amazing it sounds.

The first step was to convert the paper-based plans to a 3D CAD Model. Lou then collected the various components and timber required. The guitar is predominantly made of Tasmanian Tiger Myrtle, Rock maple and Spruce supplied by Tim Spittle from Australian Tonewoods.

Lou wanted this project to be repeatable, so he spent a lot of time writing software for his CNC and creating robust jigs and forms.

Unlike a regular guitar that has separate jigs for the body and neck this guitar required one mould for the whole guitar. This is because the neck and body meet at the headstock. The side pieces were sprayed with distilled water, wrapped in baking paper and alfoil and placed in the bending jig then into the clamping jig. This has a heat lamp inside to help the process along. After about an hour they were removed and placed into a form to hold their shape.

Next came the internal blocks and mother of pearl decorative inlays. The CNC was hard at work.

A couple of test runs of the neck and headstock assembly in MDF before cutting out the real thing. The headstock was veneered in Tasmanian Tiger Myrtle and the inlay added before the final glue up. Titebond Original was used.

The CNC really came into its own making the kerfing for the back and top, the internal braces and top Spruce veneer and rosette. Once all the braces and plates were fixed to the back of the front face it was attached to the sides and the headstock veneer applied. Next; the kerfing and side supports were glued in. Lou then applied a coat of shellac to the inside.

The back was prepared in much the same way as the front. Before attaching it, the electronic components had to be installed. Once the back was glued to the sides it was time to make it look beautiful. Channels were cut for binding and purfling and mother of pearl inlays added. The heel cap, truss rod and fretboard were added before a final sand. Next came at least 8 coats of nitrocellulose lacquer, lightly sanded after every second coat. Once this had time to cure it was rubbed down with 600 grit wet and dry sandpaper and the last components added before a coat of carnauba wax to leave a beautiful shine.

Dust Extraction Reviewed

Paul Birchall told us about his exploration of air quality motivated by the presentation by Bob Loss. Paul purchased an inexpensive air quality monitor and tested the air in his workshop.

He found that if left to self-settle the sub-2.5-micron dust would halve in 30 minutes, with his air cleaner running the amount of dust would halve in a few minutes. A significant improvement.

Paul also purchased an R2 mask from Timbecon and a Mirka sanding block that can be connected to a vacuum.